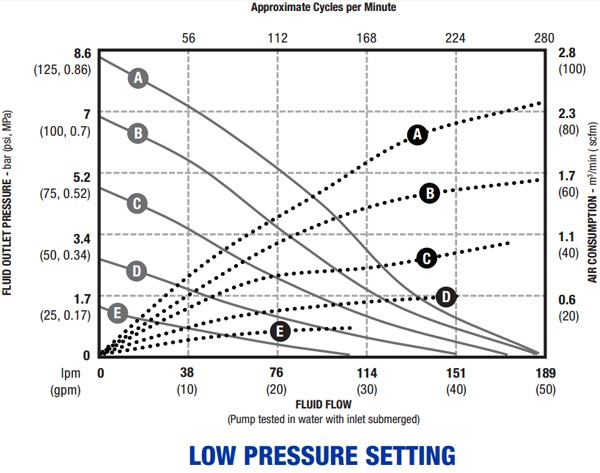

The Husky 1050HP air-operated diaphragm pump is the first pump on the market that allows users to choose between low pressure and high pressure operating modes with Graco’s low-high pressure mode valve. High pressure operation isn’t always required, so switch to the low pressure mode to reduce air consumption up to 50%. These features combined with the quality and reliability of our standard Husky diaphragm pump design; make this one of the most unique high pressure diaphragm pumps on the market.

Benefits of the Husky 1050HP Double Diaphragm Pump

· Increased fluid pressure without sacrificing flow

· Low-high pressure mode valve lets you operate the pump as a standard AODD or a high pressure AODD

· Reduce air consumption up to 50% with the low pressure mode

· Same repair parts as the Husky 1050 diaphragm pump

Overview |

Maximum fluid flow for High Pressure Mode | 50 gpm (189 l/min) |

Maximum Fluid Discharge Pressure | 125 psi (17.2 bars, 1.72 MPa) |

Maximum size pumpable solids | 1/8 in (3.2 mm) |

Fluid displacement per cycle | 0.2 g (0.76 liters) |

|

|

Husky 1050HP Performance

Looking for a repair kit? Use our pump configuration tools to select the repair kit for your pump:

· Step 1 – Go to our Pump Selector Tool

· Step 2 – Fill in your pumps part number in the right corner

· Step 3 – Get an overview of all repair kits and accessories for your pump.

· Increased fluid pressure without sacrificing flow

· Low-high pressure mode valve lets you operate the pump as a standard AODD or a high pressure AODD

· Reduce air consumption up to 50% with the low pressure mode

· Same repair parts as our Husky 1050 air-operated double diaphragm pump reduces inventory levels

· Application areas: Filter press, ceramic, high head pressure or long distance