The Husky 2200 air-operated diaphragm pump features a single piece polypropylene center section for increased reliability and chemical compatibility, plus a patented, high-reliability modular air valve that is online serviceable.

This diaphragm pump is designed with a reinforced frame for improved reliability and will help to eliminate fluid leakage.

Benefits of the Husky 2200 double diaphragm pumps

· Overall improved air efficiency

· Highest fluid flow rate in its class

· Expanded material offering to handle endless applications

· Available with Overmolded diaphragms (up to 5 times longer diaphragm life)

Overview |

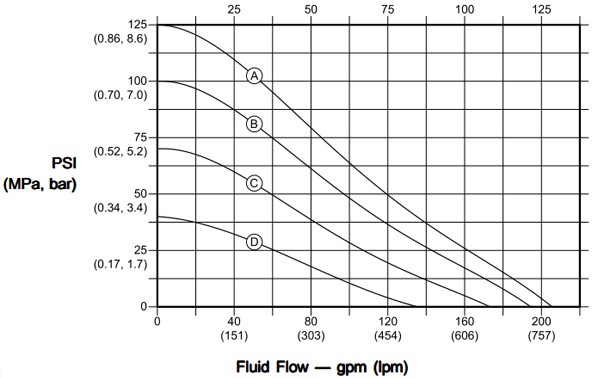

Maximum fluid flow | 200 gpm (757 l/min) |

Maximum Fluid Discharge Pressure | 125 psi (8.6 bar, 0.86 MPa) |

Maximum size pumpable solids | 3/8 in (9.5 mm) |

Fluid displacement per cycle | 1.6 g (6.1 liters) |

|

|

Husky 2200 Performance

Looking for a repair kit? Use our pump configuration tools to select the repair kit for your pump:

Step 1 – Go to our Pump Selector Tool

Step 2 – Fill in your pumps part number in the right corner

Step 3 – Get an overview of all repair kits and accessories for your pump.

功能

2 in (50.8 mm) ANSI center and end-porting options available

High flow - 200 gpm (757 lpm) in a compact, portable size

Fluid pressure to 125 psi (8.6 bar, 0.86 MPa)

Lube-free operation

Available in polypropylene and PVDF