此款 3 英寸(76.2 毫米)气动双隔膜泵采用四螺栓连接设计,能够提供稳定的密封压力,实现无泄漏运行。另外采用三部件歧管,安装方式更加灵活。可选铝合金、聚丙烯和不锈钢材质。

The Husky 3300 air operated diaphragm pump features a stall-free low pulsation air valve which provides a smooth and rapid changeover.

The one-piece center section eliminates leaks and reduces maintenance on the Husky pumps when compared to other diaphragm pumps.

Benefits of the Husky 3300 double diaphragm pumps

· Overall improved efficiency (up to 40% more efficient)

· Highest fluid flow rate in its class

· Up to 5 times longer diaphragm life compared to other air operated diaphragm pumps

· Expanded material offering to handle endless applications

· Less parts than industry peers, the complete air valve is externally accessible so it can be serviced fast and easy without removing the diaphragm pump

· Modular air valve – Stall-free, low pulsation air valve provides smooth and rapid changeover for increased efficiency and minimizes down time

· Offered in ATEX configuration.

Overview |

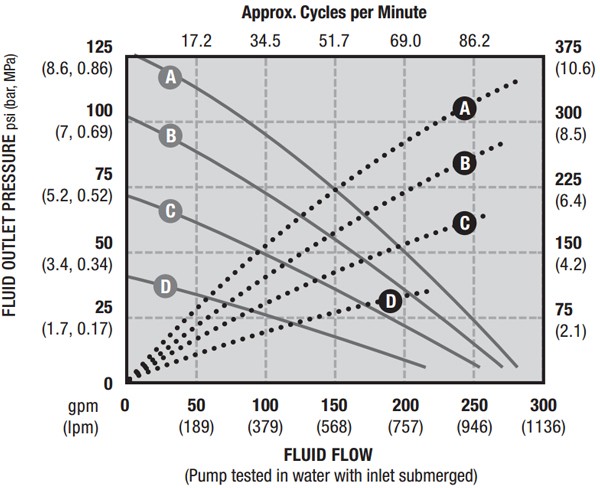

Maximum fluid flow | 300 gpm (1135 lpm) |

Maximum Fluid Discharge Pressure | 100 psi (7 bars, 0.7 MPa) |

Maximum size pumpable solids | ½ in (13 mm) |

Fluid displacement per cycle | 2.9 g (11 liters) |

|

|

Husky 3300 Performance

Looking for a repair kit? Use our pump configuration tools to select the repair kit for your pump:

Step 1 – Go to our Pump Selector Tool

Step 2 – Fill in your pumps part number in the right corner

Step 3 – Get an overview of all repair kits and accessories for your pump.

功能

提供多种材质的产品,适用于各种应用场合

流量高达 300 加仑/分钟(1,135 升/分钟)

模块化无死点空气阀设计

全系列3 英寸气动双隔膜泵系列,可选铝合金或聚丙烯材质的中心体

高强度结构

使用弹簧加压导向阀使得膜片换向更迅速